In October 2015, Green Business Norway played host to an official delegation from Bulgaria, showing the visitors three sustainable, future-oriented waste to energy options.

The Bulgarian delegation comprised environmental services professionals from local government, along with representatives of the Ecobulpack – packaging recovery organization in Bulgaria and the energy utility in the city of Sliven. The visitors’ busy agenda included visits to the Energos waste-to-energy plant in Sarpsborg, Franzefoss Gjenvinning’s production facility for refuse-derived fuel (RDF) in Oslo, and Glør’s biogas production plant in Lillehammer.

Energy from residual waste in Sarpsborg

The ENERGOS plant in Sarpsborg takes in 78,000 tonnes of household waste annually and supplies the local biochemical industry with 256 GWh of process steam, equivalent to the energy content of 22,000 tonnes of crude oil. This reduces the industry’s CO2 emissions by 50,000 tonnes a year.

Angel Angelov, CEO, and Stefan Konduzov, chairman of the board at Toplofikacia Sliven EAD, the Sliven energy utility, were very impressed by what they saw: “We’ve gained a new understanding of an advanced two-stage thermal treatment process – waste gasification and oxidation of the syngas produced in a controlled environment”, a process which gave the Bulgarian participants an important insight as far as thermal conversion is concerned.

RDF production – an alternative to energy from waste plant

Refuse-derived fuel (RDF) is an alternative for small municipalities with no plans for waste-to-energy plants but with opportunities to supply cement producers with fuel for their kilns. The Bulgarian delegation toured the Franzefoss plant in Oslo, which supplies the highest-grade RDF in Norway.

Glør – world-class sustainable waste management

Food waste is an excellent source of energy for biogas plants. Glør, an inter-municipal enterprise based in Lillehammer, has been engaged in biogas production for a number of years. This is the most sustainable way to recover energy from food waste.

Biogas production involves both energy recovery and food waste recycling. Glør’s newly upgraded plant is capable of handling 30,000 tonnes of food waste and producing 5.4 million Nm3 of biogas, 35,000 tonnes of fertilizer, and 5,000 tonnes of topsoil annually.

The next phase of the project will see the biogas upgraded to fuel. The Glør biogas station will supply fuel for commercial vehicles and private cars alike.

Glør is a Green Business Norway member business owned jointly by the municipalities of Gausdal, Lillehammer and Øyer. The company is not only the Norwegian leader in food waste processing, but also the world No. 1 in sustainable waste management.

Glør is already on course to meet the EU’s ambitious target of 80 per cent of waste recycled, 20 per cent of waste to energy, and zero per cent of waste to landfill by 2030.

Which method best meets the needs of local government in Bulgaria?

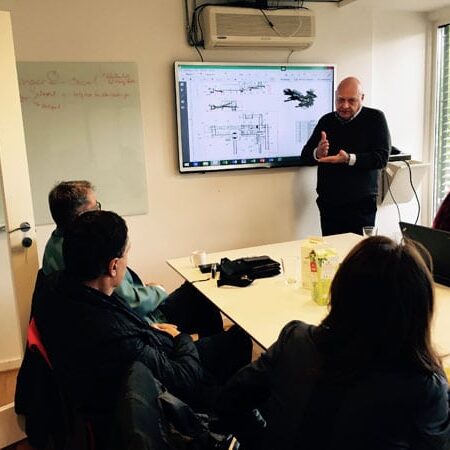

What the three plants have in common is that they have been designed for local conditions, and their strategy tailored to local needs. The Bulgarian delegation discussed possible solutions and the latest methods with Mepex Consult AS, a consulting firm specializing in waste management and recycling.

Mepex has several showpiece projects to its credit in the waste-to-energy and RDF field. An expert with a huge experience and expertise, especially on RDF production gave a presentation to the Bulgarian visitors introducing the concept of energy from waste and describing the latest trends in energy recovery.

I notice increased interest in Scandinavian know-how and best practice solutions in waste management – says GBN’s Market director in Bulgaria, Madlena Vladimirova. Our target with this visit has been to show our members’ technology, services and solutions which could be relevant for the Bulgarian development towards sustainable waste energy recovery – adds Thor Sverre Minnesjord, GBN’s CEO.

- rdf 2 lg

- rdf 1 lg

- rdf 5 lg

- rdf 4 lg

- rdf 3 lg

The Bulgarian delegation comprised Nikolai Sidjimov, chairman of the Bulgarian Association of Municipal Environmental Experts; Vidio Videv, CEO of Ecobulpack, Bulgaria’s second largest packaging recovery organization ; Angel Angelov, board chairman, Stefan Konduzov, CEO , from Toplofikacia Sliven EAD (the Sliven municipal energy utility) and Milena Angelova, an independent lawyer.

Market Director Bulgaria, Madlena Vladimirova madlena@greenbusiness.no