Miljøbil Grenland made no secret of its change of direction during the first quarter of 2011. Bernt Ausland, the company’s CEO, clasps his hands and pretends he is shaking a dice: “New deal.”

What he means is that the company has completely changed its strategy. The change attracted a lot of attention when it was announced, much of it negative. The industry and the media focused on failed electric car ambitions, executives forced out and job cuts. However, the board and the new CEO kept faith in the business. Now, at the end of the new strategy’s first year, the results are already starting to show.

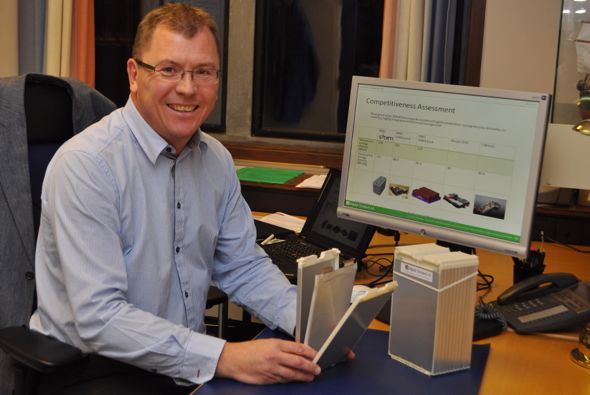

CEO Bernt Ausland of Miljøbil Grenland AS

Market leading technology

“The change of strategy took effect in the last quarter of 2010. As part of the process, a detailed survey of the world’s battery suppliers was undertaken, and it was found that we lead the world with the battery technology we are currently developing.

“These findings reinforced our belief that we are doing the right thing by refining our cutting-edge expertise in battery technology and focusing on engineering and test production. It’s an acknowledged fact that the battery is the core component of all transport systems powered by electrical energy. We’re confident that we’re now well on our way to figuring out the right solution.”

Like a jet aircraft

What can you tell us about the cutting-edge expertise Miljøbil Grenland has built up in this field?

“I like to compare the lithium-ion battery to a jet aircraft. If a lead-acid battery is a fighter plane from the interwar years, our battery is a modern interceptor. Where the interwar model has easy-to-manage, intuitive instruments and controls, the modern jet fighter is physically unstable and requires a lot of skill to operate.

“On the other hand, it’s way more efficient. The same goes for the Li-ion battery. The challenging part is monitoring and controlling the performance, environmental impact and safety of the battery cells that provide power. This is the area in which we have world-class expertise.”

The company’s 30-strong staff includes representatives of nine nationalities, and if a planned new hire goes ahead, the number of nationalities will increase to 10. Two thirds of the staff members have master’s or higher degrees, and half of them have been with the company for more than two years.

What are your ambitions as a company?

“To maintain our position as the world leader in the development and early-stage production of batteries and battery control systems. We’re not aiming to produce large volumes of batteries here at Herøya, but we have the capacity to handle pilot series.”

Does that mean you’ve put your growth ambitions on hold?

“No, we want to grow, but we’ll be sticking to designing, developing and prototyping batteries. For now, anyway, we’ll let other companies take care of volume production, integration into vehicles and sales of end products.”

Cutting-edge technology

It’s said that the real challenge lies in finding new solutions for transporting people and goods, rather than simply devising more sustainable versions of established means of transport. Are you involved in global solutions of this kind?

“Since we’ve chosen to concentrate on one area of cutting-edge technology, our main focus is not on global solutions. However, we are involved in the Norwegian E-car development program, which is examining the challenges of future transport technology. We’re supplying batteries and battery technology to eFuture, a project funded by the EU’s Seventh Framework Programme that aims at developing a carbon-neutral electric car. I recognize, too, that current electric cars have been shaped by our history of vehicles built around the internal combustion engine. If we had been unencumbered by existing car design, we would have seen a very different type of electric car.”

Entering new areas

The new strategy also paves the way for the company to explore exciting new areas of business outside the automotive sector. One such field is the maritime sector, where Miljøbil Grenland is already involved in discussions and preliminary projects.

Bernt Ausland names two examples from this sector:

“Norwegian companies are developing solutions, including both hulls and engines, aimed at providing electrical operation of private boats of all sizes. As a competency house for battery technology, we have been asked to supply battery solutions to several of these initiatives.»

“There are also several ongoing projects in Norway looking at electric speedboats and electric ferries. Here too, external partners want us to supply batteries and battery control systems. In both cases, we’re talking about twin-hulled vessels, which was the usual configuration in previous experiments with electrically powered boats.

But when it comes to ferries and speedboats, devising efficient charging arrangements presents an additional challenge.Miljøbil Grenland and other external partners have entered into a cooperation with DNV (Det Norske Veritas) in an effort to evaluate alternative solutions for these types of vessels..”

On the way out, he lets us walk through the inner sanctum, the engineering lab, where the various components of battery technology come together. The lab, and the people who work there, are the heart and brains behind Miljøbil Grenland’s muscle flexing and its determination to show the world that its new strategy is bearing fruit.